Basic Technologies

Letterpress printing was a state-of-the-art technology in Japan when DNP was originally founded as a letterpress printing firm. Since then, the company has branched out into various businesses by developing and applying printing technologies. The diverse technologies and expertise that underpin our wide range of printing operations and services are highlighted in the following pages through the example of the processes involved in printing a book.

DNP's Technologies Seen through the Printing Process

Printing Process

Technologies used at this stage of the printing process

-

1

- Project Planning

- Envisioning what output will be printed

Project planning and designing

-

2

- Information Processing

- Preparing the manuscript for printing

Information processing technologies

-

3

- Film and plate making

- Making a printing plate

Micro fabrication technology

Before actual printing, text, picture, and graphic elements are assembled into complete pages (page layout), and they are exposed on a films, letterpress printing is of exception.

With the advancements in digitalization, direct engraving is carried out with the PC workstation.

Engraving cylinder with chemical etchingTechnologies used at this stage of the printing process

Micro fabrication technology

Using technologies derived from plate making techniques in the printing process, substrates made of metal, glass, resin or other materials can be processed with extremely high precision.

Etching processing technology

Lead frames A technology for processing into desired structures by chemically corroding and removing materials that has evolved in the printing process from resin letterpress and photogravure plate manufacturing technology. In combination with photo-engraving technology it is possible to produce fine and high quality plates.

Hologram technology

Hologram on a smart card Research and development has been carried out on techniques for recording and printing three-dimensional images. Utilizing the coherent characteristic of laser light, a method for directly recording the intensity and phase of laser light reflected from actual models onto photosensitive materials, along with a method for directly recording computer-calculated optical interference fringe data with electron beam patterns.

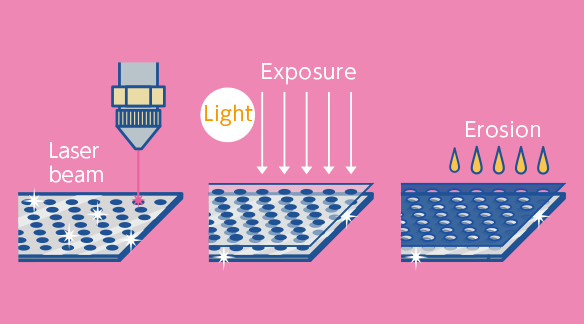

Photolithography technology

Molded photomask for a semiconductor circuit A technique to duplicate the images onto the surface of a substrate coated with photosensitive material by exposing original images using shining light or electron beams.

This technology is used in the printing process to produce printing plates from photographic film originals of images and lettering, and has been applied in industries that demand precision, such as electronics.Precision engraving technology

Marketable securities (engraved guilloche pattern) An engraved cylinder used in photogravure printing is configured as an aggregate of individual concave cells of the text and pattern, which are engraved by varying their size and depth. This engraving ranges from a manually carved one by a craftsman to those in micro-order and nano-order precision cutting equipment, and is employed in line with the desired objective.

Molding technology

Optical film Molding technology is applied to printing substrates to replicate the uneven shapes, such as text or geometrical patterns formed in the metal, glass or resin molds originally used. It was developed from an embossing process performed to align printing patterns and from the machining of lenticular lenses used for 3D printing.

-

4

- Printing

- Transferring ink onto paper

Precision Coating

-

5

- Binding and Post-processing

- Folding, gathering, and binding

Post-processing technologies

Technologies that underpin the printing process

-

- Materials Development

- Organic synthesis technology, distribution and mixing technology, color and photosensitive materials and polymeric materials

-

- Evaluation and Analysis

- Analysis planning, analysis technology, process and material diagnosis technology, simulation technology, and analysis information database technology