What is Retardation Film?|Explaining Principles and Types

Retardation films are optical components designed to enhance the contrast and expand the viewing angle of displays.

Liquid crystal displays (LCDs) and OLED(Organic Light Emitting Diode) displays are used in a wide variety of applications, from televisions to smartphones. However, both LCDs and OLEDs face issues such as color distortion and reduced contrast caused by reflections from sunlight and ambient light.

The main cause of color distortion in LCDs is the optical shift (retardation) that occurs when light from the backlight passes through the liquid crystal layer. To address and compensate for this optical shift, retardation films have been developed.

In OLED displays, contrast reduction is caused by the reflection of sunlight and external light onto the electrodes. To minimize this impact, a circular polarizer, which combines a linear polarizer and retardation film, is used to reduce the reflection of external light.

*The above information is as of December, 2023.

- Principle of retardation film

- Types of retardation film

- DNP's retardation film

- DNP's optical film

- DNP for development and manufacture of retardation film

Principle of retardation film

An OLED display consists of a layer sandwiched between electrodes on both sides. While this is not noticeable in dim environments, ambient light in well-lit surroundings reflects off the electrodes, resulting in unwanted white reflections and reduced contrast. To address this issue, a linear polarizer and retardation film are incorporated to effectively reduce the reflection of external light from the electrodes.

When external light, with random polarization, enters, it is first converted to linear polarization by the linear polarizer and then transformed into circular polarization by the retardation film. The light reflected by the OLED light-emitting cell (electrode) acquires an opposite circular polarization, which is then converted back to linear polarization by the retardation film. However, at this stage, the linear polarization is rotated by 90° compared to when it entered as incident light, preventing it from passing through the linear polarizer. This combination of the linear polarizer and retardation film efficiently reduces the reflection of ambient light, minimizing white reflections and preventing a reduction in contrast.

|

|

Types of retardation film

There are two main methods for introducing a retardation function to films: the stretching method and the coating method.

Stretching method: In the stretching method, the film's molecular orientation is altered through directional stretching. Polymer films consist of interwoven chains of polymers that are drawn to create a uniform arrangement, thus creating the retardation function.

Coating method: In the coating method, liquid crystal materials are applied to the film and undergo alignment treatment. Liquid crystal materials have various structures, but nematic liquid crystals are commonly used due to their rod-shaped molecular configuration. For the alignment film, by rubbing with a cloth or exposing to polarized light, the liquid crystal molecules can be oriented in a desired direction, resulting in the creation of the retardation function.

DNP's retardation film

|

|---|

DNP utilizes its expertise in printing and thin film coating to manufacture retardation films using liquid crystal materials through the "coating method." The advantage of this method is that it allows for the production of thinner films compared to those stretched in a specific direction. This reduced thickness ensures flexibility, making the film ideal for applications in flexible OLED displays, such as foldable smartphones.

DNP's optical film

In addition to retardation films, DNP also produces high-performance optical films like AR film and AG film on a large scale. These optical films, when combined with retardation film, enhance the visual appeal of displays even further.

Anti-reflection film(AR film)

|

|---|

AR film, and LR film(Low-reflection film) are optical films with an anti-reflection layer. By taking advantage of light interference at the AR layer, reflected light can be reduced on a screen, and its transmittance can be improved.

AR film reduces the effects of ambient light on display screens and allows them to be seen more clearly.

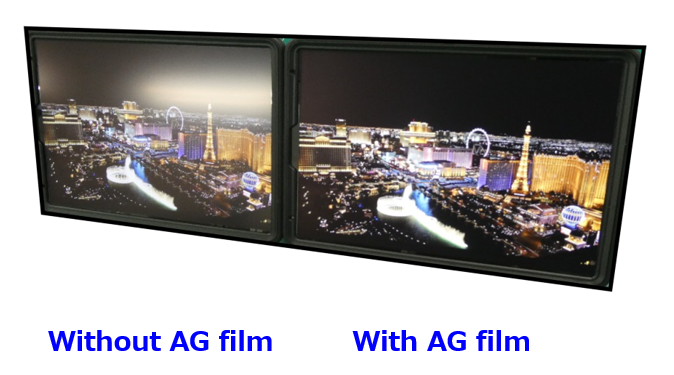

Anti-glare film(AG film)

|

|---|

AG film reduces outside light reflection by diffusely reflecting incident light on an uneven surface, distinct from AR film utilizing light interference. AG film uses a hard coat layer with deposited particles on the base film to achieve its effect, unlike AR film which relies on light interference. These films can even be combined for further reduced ambient light reflection.

DNP for development and manufacture of retardation film

At DNP, we have a wealth of expertise in Retardation film design and manufacturing. Please contact DNP for Retardation film development and manufacturing. With DNP, various proposals are possible to meet your specific needs.

Other columns and featured articles

-

DNP's Display Enhancement Films: AR, AG & Reta...

- Display Components

We will elucidate the principles and applications of DNP's display enhancement films, including AR f...

-

What is AR Coating? Explanation of the difference ...

- Display Components

AR coating, where AR stands for Anti-Reflection, is a technology that involves applying an anti-refl...