Development and manufacturing of custom optical films using proprietary optical design

Anti-Reflection Film (AR Film)

Anti-reflection film (AR film), and Low-reflection film (LR film) are optical films with an anti-reflection layer. By taking advantage of light interference at the AR layer, reflected light can be reduced on a screen, and its transmittance can be improved. AR film reduces the effects of ambient light on display screens and allows them to be seen more clearly.

- Principle of AR film

- Difference between AR film and AG film

- AR film applications

- DNP's strengths in AR film development and manufacturing

- Product lineup

- DNP for development and manufacture of AR film

- DNP in Electronics

|

|

Principle of AR film

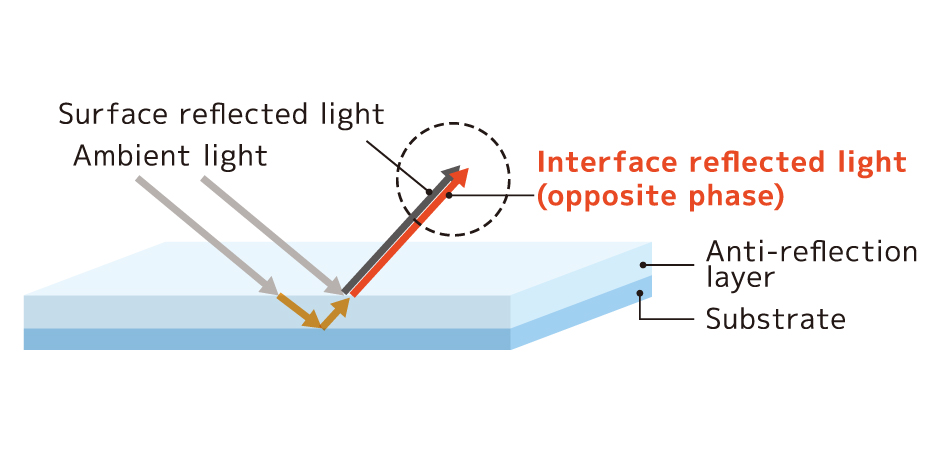

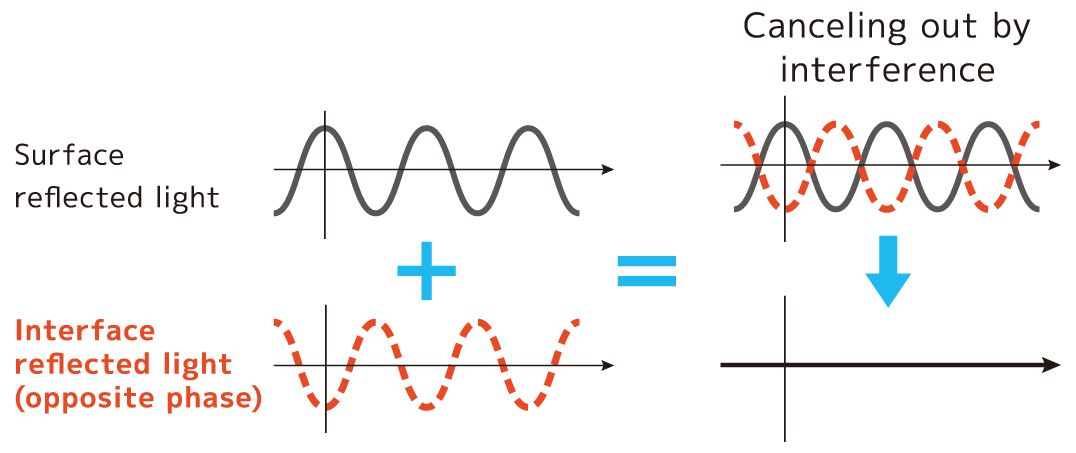

The material is designed so that the light reflected on the surface of the AR layer has the same amplitude and opposite phase as the light that is transmitted through the AR layer and reflected at the interface between the AR layer and the base film substrate. This design allows the two reflected lights to interfere and cancel each other out, weakening them and preventing them from reaching the eye.

|

|

|

Difference between AR film and AG film

|

|---|

Anti-glare film(AG film) aims to achieve a similar effect. While AR film makes use of light interference to achieve it effect, AG film exhibits surface unevenness through the application of a hard coat layer with particles deposited on the surface of the base film substrate, which reduces the reflection of ambient light through diffuse reflection of incident light on the uneven surface.

It is of course possible to combine both AR and AG film to further reduce the reflection of ambient light.

AR film applications

AR film is used on the top surfaces of displays of TVs, PCs, tablets, and smartphones.As with other film used for displays, since it is used on the top surfaces of displays, the film must have scratch resistance, chemical resistance, antifouling, and antistatic properties in addition to exhibiting sufficient transmittance and haze values.

DNP's strengths in AR film development and manufacturing

Optical designs can be optimized for any given situation

Reflection color control

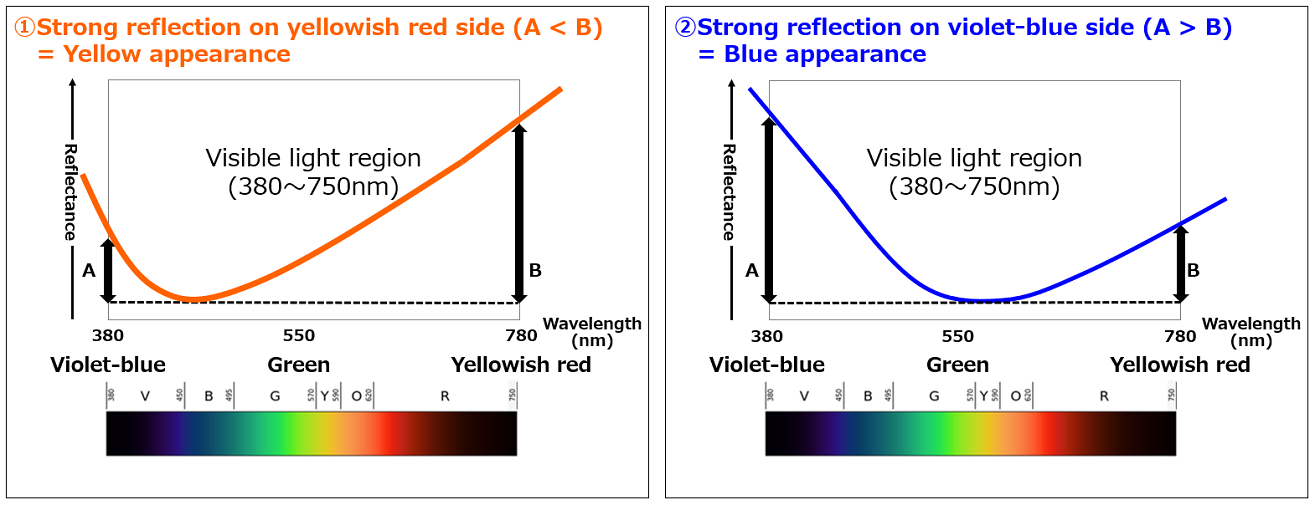

The graph below shows the relationship between the "reflectance" and "wavelength" of light. The color of light reflected from AR film is dominated by the color of wavelengths with high reflectance. As the thickness of the AR layer increases as shown going from ① to ②, the spectral reflection shifts and the reflected color changes. In addition to this, if there is fluctuation in film thickness within the display surface, the variation of the reflected color will increase, resulting in the display giving off an unnatural impression to viewers.

Therefore, precise control of reflectance and film thickness is necessary to avoid adversely affecting the color tones of the display. If the thickness of the coating varies by even a few nm, the product will not function as expected. DNP develops optimal products, achieving precise control of film thickness with our advanced product design and processing technologies.

|

|

Reflectance (Light interference) control

In order to reduce reflectance, it is essential to reduce the refractive index of the AR film. However, if only refractive index reduction is pursued alone, substances such as water and alcohol would cause degradation and as a result, transparency and scratch resistance would not be maintained. For that reason, the film must be optimally designed for the situation in which it will be used.

Achieving low reflection (0.1% reflectance)

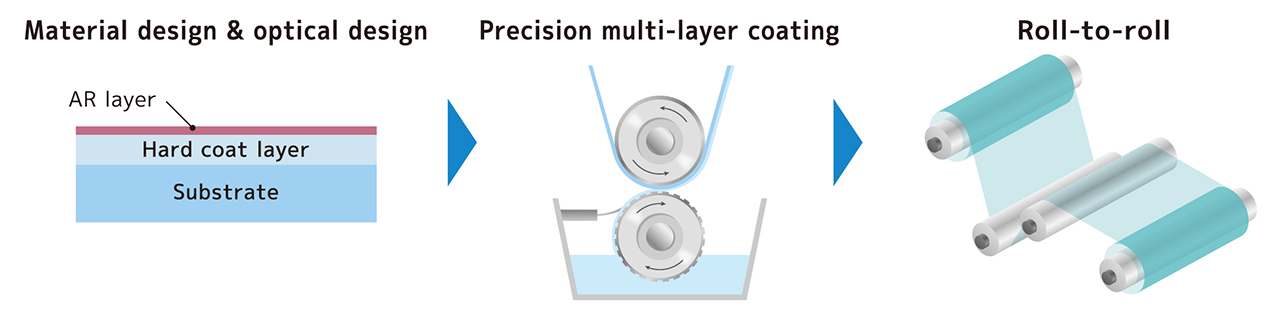

AR film manufacturing methods include the "vacuum deposition method," the "sputtering/CVD method," and the "wet coating method." At DNP, we employ the wet coating method, due to its relatively high productivity, which enables us to produce highly functional products with a reflectance of 0.1%, and achieve a sufficient level of hardness at the same time.

Strength in manufacturing technology

|

|

Starting from ink design for high quality

In order to achieve both hardness and target refractive index in AR film, we have developed and employed a variety of particles, resins and additives, and furthermore, by combining these materials in a well-balanced manner, we maximize film functionality. Additionally, We optimize the physical properties of our ink, such as the viscosity and surface tension, to enable precise application during the processing of the highly productive wet coating method.

Production facilities capable of multi-layer coatings up to 3 layers

Multi-layer coating technology is necessary to provide high quality products at lower cost. At DNP, we have manufacturing facilities capable of producing multi-layer coatings up to 3 layers, enabling us to mass-produce multi-layer AR film with features such as antistatic, hard coat, and low reflectance.

Uniform coating possible even at ultra-wide 2,500mm

The demand for wide film is increasing due to the growing size of LCDs. At DNP, we have production lines capable of producing products up to 2,500 mm wide, and our advanced process technology enables us to apply uniform coatings to these wide products.

A variety of add-on features

Antistatic function

We apply the optimal antistatic agent according to the desired characteristics of the AR film, so that dust and other particles are prevented from adhering to the film due to static electricity, while maintaining high transparency and hardness.

Scratch protection

One of the most important functions of AR film used on a top surface is to prevent scratching. DNP performs optimal product design to achieve scratch resistance while still suppressing screen surface reflection and glare.

Antifouling function

This function prevents fingerprints, ink, and other smudges from sticking to surfaces, while at the same time making it easier to wipe off any smudges that do get applied. This is an absolutely essential feature for film used on the top surface of touch panel displays.

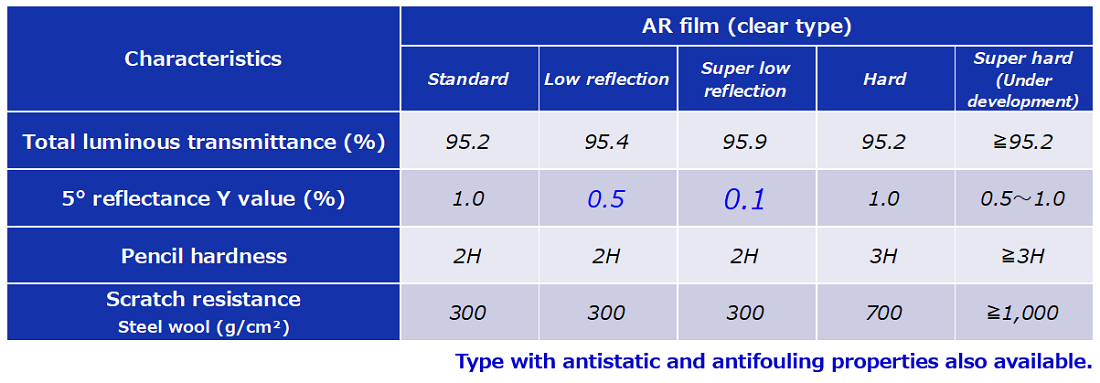

Product lineup

Multiple products with different reflectance and hardness levels are available.

|

|

For more detailed data, please contact us.

DNP for development and manufacture of AR film

At DNP, we have a wealth of expertise in AR film design and manufacturing. Please contact DNP for AR film development and manufacturing. With DNP, various proposals are possible to meet your specific needs.

We accept inquiries from corporate customers only.

DNP in Electronics

|

|

Other than listed above, DNP’s Electronics segment has a wide range of products for digital interface (display-related) and semiconductor.

You can check further our product line-up here and find anything to accommodate your needs.