DNP Achieved Over 85% Repulpability for High Barrier Paper Mono-Material Sheet

Achieves both renewable resource recycling and high barrier properties

Jun25,2024

Tokyo, June 25, Dai Nippon Printing Co., Ltd. (DNP) has successfully updated the materials and processing methods used in a proprietary mono-material sheet for packaging product to achieve over 85% repulpability1.

In 2022 we developed an environmentally friendly packaging sheet with high barrier properties2 that prevents the transmission of oxygen, and water vapor as packaging materials for food, cosmetics, and medical products. At the same time, the use of mono-material paper facilitated increased recyclability.

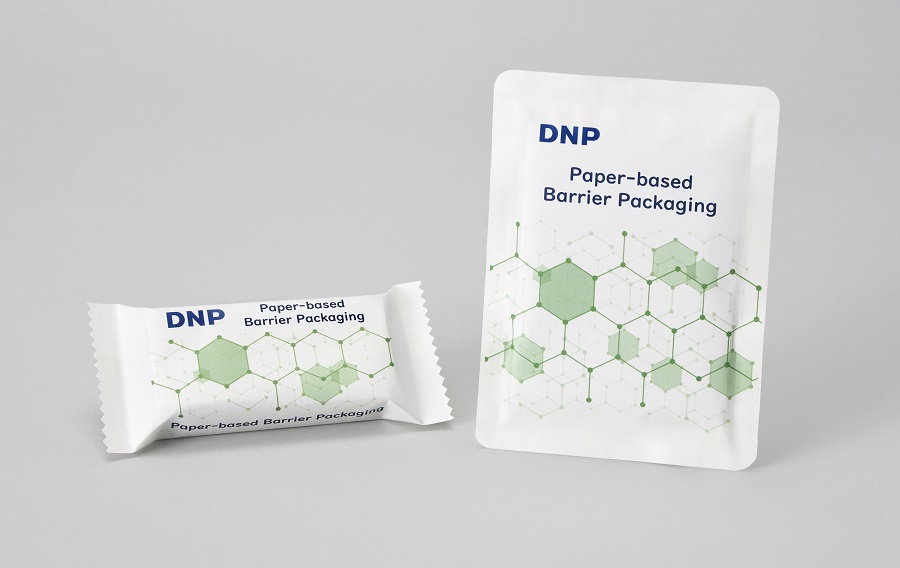

Image of updated packaging employing paper mono-material sheet

Development

In order to solve environmental issues such as climate change, global warming, and marine pollution caused by plastics, global major manufacturers and the retail distribution industry are working to reduce the environmental impact when developing and providing products by switching from petroleum-based to plant-based materials, and using compostable and biodegradable materials, instead. In recent years, as an indicator of eco-friendliness in the recyclability of paper packaging, efforts have been witnessed in Europe and the United States to improve the recycling effect of paper as a renewable resource, by increasing the repulpability to more than 80%.

In response to these challenges, DNP is putting efforts into expanding our line-up of eco-friendly packaging3. In this latest development, we have further improved the high barrier paper mono-material sheet for packaging developed in 2022, and will commence the provision of a revamped product with advanced recyclability that also maintains barrier-free features.

By achieving over 85% repulpability we have successfully developed a product that contributes to the realization of a recycling-oriented society. Paper is a naturally renewable resource, and by increasing its use we will reduce the use of non-renewable petroleum-derived materials, leading to reduced CO2 emissions throughout the entire supply chain. The high barrier function will also help reduce food loss and inventory disposal.

High Barrier Paper Mono-Material Sheet Features

1. Contributing to the recycling of paper packaging resources by increasing the repulpability in the recycle property evaluation to 85%.

General craft paper and cardboard are used as mono-material base materials. By improving the materials used and processing methods, the repulpability in recycle property evaluation has been increased to 85%, contributing to further resource recycling of paper packaging.

2. Achieving high barrier properties in paper packaging

Paper has a porous structure with fine gaps between the fibers. Consequently, it has so far been difficult to provide a barrier against oxygen and water vapor, making it difficult to protect contents for extended periods of time when used as a packaging material. It was considered difficult for paper to achieve high barrier properties, but in response to this challenge, DNP has leveraged its proprietary converting technology to achieve oxygen transmission rate (OTR) of 0.5 cc/m2/day/atm4 or less, and a water vapor transmission rate (WVTR) of 0.5 g/m2/day5 or less.

3. Achieves high barrier performance and high repulpability from thin paper to thick paper

Compatible with a variety of paper, including not only thin craft paper, but also thick paperboard, or cardboard. The updated product achieves a high barrier performance, along with a high repulpability , while minimizing the deterioration of barrier properties following folding to attain the functionality required for packaging.

4. Transparent high barrier film prevents the intrusion of metal fragments during recycling.

The high barrier film is composed of thin, transparent material and does not contain the plastic polyvinylidene chloride (PVDC). In addition, as no aluminum deposition coating or aluminum foil is used, there is no risk of metal fragments intruding during recycling that could lead to degrading of the recycled pulp.

Going forward

DNP will provide high barrier paper mono-material sheet to manufacturers of food, cosmetics, and medical products. We will also leverage our proprietary converting technology, to expand our lineup of environmentally friendly products and services with enhanced barrier properties, and will deploy them in the global markets where demand for reducing environmental impact is growing.

The product will be exhibited at the DNP booth located at East Hall 3, Booth No. 21-46 at INTERPHEX JAPAN 2024 - 26th Int'l Pharmaceutical and Cosmetics Manufacturing Expo to be held at Tokyo Big Sight from June 26 to 28, 20246.

1: The repulpability varies depending on the basis weight of the paper.

2: For further information about High Barrier Paper Mono-material Sheet for Packaging https://www.global.dnp/news/detail/20167671_4126.html

3: For further information about Eco-Friendly Packaging https://www.dnp.co.jp/eng/biz/solution/products/materials_package.html

4: OTR: The amount of oxygen that passes through a 1 m2 film in a 24 hour period at 1 atmosphere (atm).

5: WVTR: The amount of water vapor that passes through a 1 m2 film in a 24 hour period.

6: For further information about INTERPHEX JAPAN 2024, please visit https://www.dnp.co.jp/biz/eventseminar/event/20173876_4966.html (in Japanese only)

* Product prices, specification and service contents mentioned in this news release are current as of the date of publication. They may be changed at any time without notice.