Business Details

DNP Fine Chemicals strives to contribute to society and connect the present to the future through technology in order to create "Tomorrow's Basic (products that will be taken for granted in the future)".

We develop new technologies that will contribute to the society of tomorrow at our Tsukuba Development Center and DNP Fine Chemicals Utsunomiya.

Material design technology, processing dispersion technology, resin synthesis technology, and material evaluation technology

Our technological development team with advanced knowledge and technological skills is devoted in developing products.

We strive to respond quickly to changes in the chemicals field, an area of intense technological innovation, so that we can meet the needs of our clients in a conscientious and elaborate manner.

Display Materials

Display materials: We support the advanced information society of the future with technology that makes possible highly reliable displays with high-resolution, wide color gamut, and low power consumption.

|

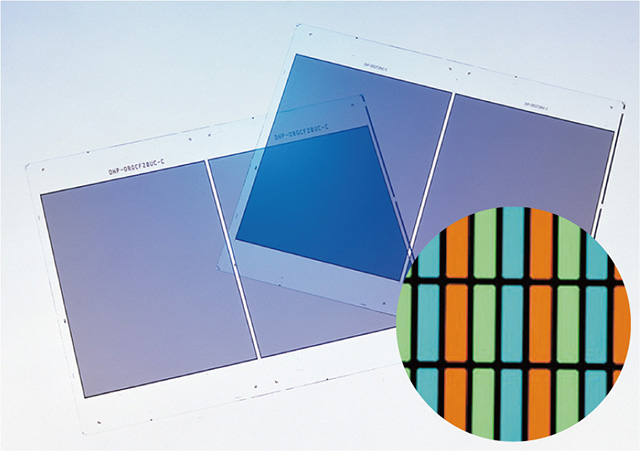

Color resist for color filters |

- Color resist products

- Each color filter in an LCD display has aligned red, green, and blue rows, and the material that colors those apertures is color resist.

The high quality and reliability of our color resist products, which are also used by large number of customers overseas, have been verified in a broad range of applications, including displays of all sizes, mobile devices, monitors, and televisions, including display equipment used in vehicles and healthcare.

In 2015, we developed a dye-based blue color resist with high-luminance, high- transmittance, and high-heat resistance as an alternative to the existing blue pigment-based color resist. - Overcoat materials

- This clear material protects the surface of color filters.

- Low temperature post-bake color resist

- The forming of color filters through a low-temperature process was made possible by utilizing resin synthesis and photolithography technologies.

It is expected to make possible, especially, the development of flexible displays that are foldable, bendable, and rollable.

Imaging Materials

Imaging materials: We support printing in the digital era with solid material technologies.

|

Inkjet ink loaded on a inkjet printer |

- Inkjet ink

- We supply ink for inkjet printers with a wide color gamut and exceptional durability, including inkjet ink for commercial signage, based on dispersion technology and resin synthesis technology that we have refined for many years.

- Dye-sublimation transfer imaging materials

- Our dye-sublimation transfer imaging materials provide key technology for Ki-Re-i photo kiosks at train stations and other facilities as well as the PrintRush self-service photo system found at various stores.

- Thermal transfer imaging materials

- Our thermal transfer imaging materials allow barcodes used in distribution to be printed on demand. Thermal ribbons that allow barcodes to be printed by means of thermal transfer are used in that application.

Electronic Industry Materials

Electronic industry materials: Our products make possible the precision working technology that evolves daily.

|

Electronic components such as semiconductor wafers |

- Adhesives

- Our temporary adhesives are used in the manufacture of electronic components such as semiconductor wafers and magnetic materials (in polishing and cutting processes).

- Cleaning liquids

- We supply both organic and inorganic alkali cleaning liquids. These products are effective at removing temporary adhesives from polishing plates.

- Etching solutions

- Etching solution removes unnecessary portions in semiconductor and LCD circuit formation processes. Our products in this category provide excellent wettability with regard to photoresist and feature a chemical composition that is suited to the formation of high-precision circuits.

- Developing liquids

- Our developing liquids have an inorganic alkaline ingredient that is used to develop resist in the production of semiconductor photomasks. These products make possible the high-quality development with excellent dimensional reproducibility.

- Conductive pastes

- Our thermosetting silver pastes are used in applications such as touch panel wiring.

Functional Materials

Functional materials: We support state-of-the-art electronics with creative element technologies.

|

Displays and other peripherals |

- Molding materials

- Molding technology, which transfers the shape of a source plate to resin, is used in a variety of fields.

- Hard coat materials

- Using UV curing technology as a key technology, we design and propose a variety of functional materials, including protective materials, hard coat materials, and photolithography materials that are instrumental in the electronics and photonics fields.