Corporate History

1876

Shuei

Shueisha founded in Yazaemon-cho, Sukiyagashi-gomongai (now Ginza, Tokyo)

1877

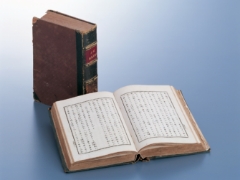

Shuei

Printed revised edition of Self-Help (Japan's first domestic printed book using letterpress printing with Western-style binding)

1878

Shuei

Adopted first company rules, defining printing as a "Civilized Business"

1881

Shuei

Began casting printing type

1882

Shuei

Founded Seibundo and began selling printing type

1886

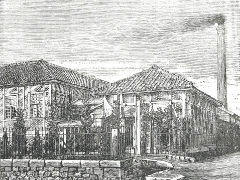

Shuei

Opened Ichigaya plant in Tokyo

1889

Shuei

Teiichi Sakuma became President

1890

Shuei

Began printing the Kokumin Shimbun daily newspaper and established a branch factory within Minyusha

1891

Shuei

Teiichi Sakuma established Insatsu Zasshi Co., Ltd. and issues Printing Magazine

1894

Shuei

Shueisha registered as a joint stock company

1895

Shuei

Completed expansion of the main factory, Japan's first building using a steel frame and bricks

1899

Shuei

Printed Osaka Municipal port construction bond certificates using intaglio plates

1907

Nisshin

Nisshin Printing Co., Ltd. established in Enokicho, Ushigome-ku (now Enokicho, Shinjuku-ku)

1910

Shuei

Seibundo issued Type Specimens

1912

Shuei

Revision of Shueitai font completed

1916

Shuei

Offset printing press for duodecimo installed at Ichigaya Plant (offset printing begins)

1923

Shuei

The head office and Seibundo in Ginza were destroyed by fire in the Great Kanto Earthquake, head office relocated to Ichigaya Kagacho, Ushigome-ku, Tokyo

1924

Shuei

Printed King magazine Dai-Nippon Yubenkai Kodansha

1926

Shuei

Rebuilding of Ichigaya Plant completed, construction of sales office building (currently Ichigaya Letterpress Factory)

Shuei

Printing of Gendai Nihon Bungaku Zenshu ("Complete Anthology of Modern Japanese Literature") by Kaizosha (start of the "one-yen book" boom)

1927

Nisshin

Merger with Ichida Offset Printing Works

Shuei

Opened Ginza type sales office

1928

Nisshin

Nisshin Printing Co., Ltd. acquired Tsujimoto Shashin Kogeisha. Began Japan's first gravure printing in primary colors

1932

Nisshin

Osaki Plant opened

1935

Launch of Dai Nippon Printing Co., Ltd. following merger between Shueisha and Nisshin Printing Co., Ltd., Giichi Masuda became President

1941

Hiromu Aoki became President

The Pacific War begins

1943

Chokichiro Sakuma became President

1944

Launched the Technical Research Laboratory

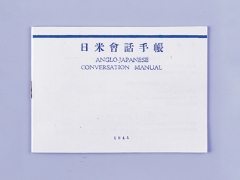

1945

Printing of Nichibei Kaiwa Techo ("Anglo-Japanese Conversation Manual") by Kagaku Kyozaisha.

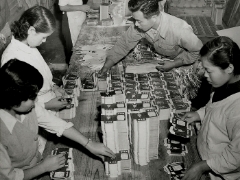

1946

Four plants placed under the control of the Ministry of Finance to print Bank of Japan notes

Opened Kyoto Plant

1949

Listed shares on Tokyo Stock Exchange

Began printing stock certificates at Enokicho Plant

1950

Established paper container line within Kyoto Plant

1951

Announced five-year reconstruction plan aimed at expanding areas of business

Began printing on vinyl, cellophane, cloth and other materials

Osaki Plant opened as a dedicated paper container production facility

1952

Received order from Japan Tobacco and Salt Public Corporation for printing of cigarette box packaging

Succeeded at producing plates for endless multicolor gravure printing; began printing decorative melamine plates (for Sumitomo Bakelite)

1953

Acquired New Tokyo Securities Printing Co., Ltd. (predecessor of the Oji Plant)

Japan's first supermarket, Kinokuniya, opened in Aoyama, Tokyo

1955

Orie Kitajima became President

Printed Kojien dictionary (Iwanami Shoten) using DNP's original font, Shueitai

1956

Printed Shukan Shincho, the first weekly magazine issued by a publishing company in Japan

Opened Osaka Plant, merger with Nihon Seihan Co., Ltd.

1957

Opened Oji Plant

1958

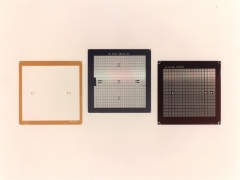

Became first in Japan to succeed in producing prototypes of shadow masks used in color televisions

1959

Printed Shonen Magazine (Kodansha) and Shonen Sunday (Shogakukan)

Succeeded in producing prototypes for vapor deposition masks for mesa transistors

Printed plastic bags for Chicken Ramen (Nissin Foods)

1960

Opened plant in Saitama Prefecture north of Tokyo, specializing in electronics devices

Toshiba Corp. unveiled Japan's first domestically produced color TV; NHK and four other broadcasters began color television broadcasts

1961

Established Dai Nippon Polymer Co., Ltd. (now DNP Technopack Co., Ltd.) and began blow-molding of bottles

Established Central Research Institute

Succeeded in printing in color directly onto metal plate for the first time in Japan

Manufactured photomasks (emulsion masks)

1962

Established Metalprint Co., Ltd. (now DNP Ellio Co., Ltd.) as a joint venture between DNP and Fuji Iron & Steel (now Nippon Steel Corporation)

Began producing paper cups

1963

Established Hokkaido Beverages Co., Ltd. (renamed Hokkaido Coca-Cola Bottling Co., Ltd.)

Introduced business unit system

1964

Established Dai Nippon Printing (Hong Kong) Co., Ltd.

Printed admission tickets, commemorative stickers, posters, etc. for the Tokyo Olympics

Began producing lead frames

1965

Developed gravure fabric printing technology

Entered into business tie-up with Standard Register, Inc. and started mass production of business forms

1967

Manufactured photomasks (hard masks) for semiconductors

1968

Opened Yokohama Plant, specializing in paper containers

Established the Creative Design Center, specializing in planning and production

Opened New York representative office

1969

Opened representative offices in Sydney and Frankfurt

Established Shikoku Dai Nippon Printing Co., Ltd. (now DNP Shikoku Co., Ltd.)

Began producing laminate tubes

1970

Planned and designed nine international pavilions for the Japan World Exposition, including the Saudi Arabia pavilion

Established Dai Nippon Printing (Europa) GmbH (now DNP Europa GmbH) in Düsseldorf, West Germany

1972

Established a joint venture, Dai Nippon Gitakarya Printing Co., Ltd. (now PT DNP Indonesia) in Indonesia

Merger with Futaba Printing Co., Ltd. and began operating it as DNP's Akabane Plant

Established CTS Dai Nippon Co., Ltd. Commercialized computerized typesetting system (CTS) in Japan

Opened Warabi Plant in Saitama Pref. north of Tokyo

1973

Opened Sayama and Tsuruse plants in Saitama Pref.

Opened Nara Plant

Established framework for mass production of magnetic-stripe plastic cards

1974

Established DNP America Inc.

Began full-scale production of magnetic-stripe bank passbooks

Introduced "Curlfit" technology for printing on curved surfaces

1975

Established Manufacturing Technology Laboratory (now Manufacturing Technology Integration Laboratory)

Established retort pouch food packaging technology

Developed wood-grain synchronized embossed finish olefin sheets

1976

Developed liquid paper containers for beverages (L carton system)

Developed aseptic filling system for single-portion packages of Snow Brand Milk Products Co. Ltd.'s coffee whitener

1978

Developed large, three-dimensional holograms that served as prototypes for Lippmann holograms

1979

Opened Neyagawa Plant in Osaka

Yoshitoshi Kitajima became President and Orie Kitajima became Chairman of DNP

1980

Developed aseptic filling system for Bag in Box (BIB) containers

1981

Developed "MD-1" specialized containers for Meiji Bulgaria Yogurt

Developed fully automated photomask manufacturing equipment

1982

Developed carrier tape for transporting precision electronic components

Began producing polyethylene terephthalate (PET) plastic bottles

1983

Commercialized "Thermoject" technology for decorating molded plastic products

Opened Kuki Plant in Saitama Pref.

Developed re-writable smart cards (smart card prototype)

Produced the third edition of Kojien dictionary (Iwanami Shoten) using a computerized typesetting system (CTS)

Began producing rear-projection television screens

1984

Developed technology for mass-producing rainbow holograms using transfer printing

Opened electronic products plant in Kyoto City

Established production technology for thermal transfer printing media and began production

1985

Completed construction of our Central Research Institute's Kashiwa Laboratory in Chiba Pref. east of Tokyo

Produced Japan's first CD-ROM dictionary: Dictionary of Science and Technology (Sanshusha Publishing Co., Ltd.)

Developed dye-sublimation thermal transfer printing media technology and began production

Developed technology for producing color filters used in liquid crystal displays

1986

Opened Ginza Graphic Gallery (ggg)

Developed material for use in prosthetic joints

1987

Developed urine testing paper using printing technology

1989

Delivered first version of DNP's "High-definition Gallery" image display system to the Museum of Fine Arts, Gifu

Established smart card production joint venture Spom Japan Co., Ltd. with Bull SA of France

Established DNP Denmark A/S to manufacture and sell projection TV screens

1990

Established DNP Singapore Pte. Ltd.

Developed "S-Mail" postcards with a full adhesive cover that peels off easily

1991

Opened Tsukuba Center for Integrated Development in Ibaraki Pref. north of Tokyo

Opened Ono Plant in Hyogo Pref. west of Kyoto

Opened Okayama Plant

1992

Developed PET plastic bottle pre-forming method

1993

Launched support services for official J.League (soccer) Data Site

Opened Shiraoka Plant in Saitama Pref.

Opened Mihara Plant in Hiroshima Pref. in western Japan

Developed contactless smart cards

1994

Established Dai Nippon IMS America Corp. (now DNP Imagingcomm America Corp.)

Launched DNP website

1995

Invested in Vietnam reforestation joint venture with Shin Oji Paper Co., Ltd. (now Oji Paper Co., Ltd.) and Nissho Iwai Corp. (now Sojitz Corp.)

Began Media Galaxy internet services

Opened Tanabe Plant in Kyoto Pref. (now Kyotanabe Plant)

1996

Began producing EB-coated paper for use in decorative materials

Established technology for designing AR (Anti-reflection) film for liquid crystal displays

Developed manufacturing technology for electrodes used in lithium-ion batteries

Opened Izumizaki Plant in Fukushima Pref., in northern Japan

1997

Developed inline aseptic filling system for PET plastic bottles

1998

Began selling transparent vapor deposition film, a non-PVC film with excellent barrier properties

Opened Utsunomiya Plant in Tochigi Pref. north of Tokyo

Developed mass production technology for "True Image" full-color Lippmann holograms and began production and sales

Established DNP Taiwan Co., Ltd.

1999

Opened Ushiku Plant in Ibaraki Pref.

Developed smart cards that can be used for both contact and contactless applications

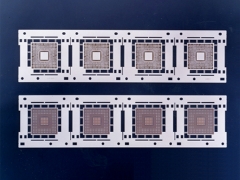

Developed ultra-high density multi-layered substrates for use in semiconductor packages

Commercialized soft packs for lithium-ion rechargeable batteries

2000

Opened Internet Data Center

Developed and began producing contactless "AccuWave" IC tags

Established DNP Korea Co., Ltd.

2001

Succeeded in developing a flexible color organic EL display

Began supplying "FOMA cards" for NTT DoCoMo cell phones

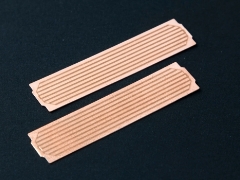

Developed vapor deposition masks (metal masks) for OLED displays

2002

Collaborated with STMicroelectronics to establish DNP Photomask Europe S.p.A. in Italy

2003

Opened Maison des Musées de France in Ginza (now Maison des Musées du Monde)

Developed components for solar battery modules

2004

Developed new screen for use with front projectors

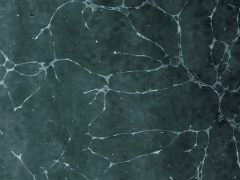

In collaboration with Tokyo Medical and Dental University, succeeded in forming capillary blood vessel patterns

Began selling PrintRush self-service digital photo printing systems

2005

Established DNP International Trading (Shanghai) Co., Ltd.

Opened Kurosaki Plant in Kitakyushu City, in southern Japan

2006

Acquired ID photo and related businesses from Konica Minolta Holdings, Inc.

Opened Kamiya Solutions Center

Opened the Louvre-DNP Museum Lab, a joint project with the Louvre Museum

2007

Developed Japan's first packaging for Japanese-style space food

2008

Established DNP IMS Netherlands B.V. in the Netherlands (now DNP Imagingcomm Europe B.V.)

Established DNP Foundation for Cultural Promotion

TRC Library Service Inc. and Maruzen Co. Ltd. become consolidated subsidiaries

2009

Junkudo Co., Ltd. becomes a consolidated subsidiary

Established DIC Graphics Corp. jointly with DIC Corp.

2010

Established CHI Group (now Maruzen CHI Holdings Co., Ltd.); Maruzen Co., Ltd. and TRC Library Service Inc. became subsidiaries of CHI Group

Intelligent Wave becomes a consolidated subsidiary

Began operating a hybrid bookstore network, providing both paper and electronic books

2011

Opened Tobata Plant in Kitakyushu City, in southern Japan

Developed a biomass plastic film for packaging materials

2012

Business tie-up with Nihon Unisys, Ltd. (now BIPROGY)

2013

Opened Vietnam Plant, specializing in flexible packaging

Full-scale start-up of DNP Fine Chemicals Utsunomiya Co., Ltd.

Established Dai Nippon Printing (Thailand) Co., Ltd.

Opened dye-sublimation thermal transfer printing media plant in Malaysia

Began operations of DNP Kashiwa Data Center

2014

Established a representative office in India

Opened DNP Kyoto Uzumasa Cultural Heritage Gallery

Developed multifunctional insulation box

2015

Developed reflective film for agricultural use

Acquired Tamura Plastic MFG. Co., Ltd. as a consolidated subsidiary under the name DNP Tamura Plastic Co., Ltd.

2016

Held Globes in Motion exhibit in collaboration with the Bibliothèque Nationale de France

Launched the Cyber Knowledge Academy

Opened DNP Plaza in Ichigaya, Tokyo

2017

Produced a replica of the Japan-Denmark Treaty of Friendship, Commerce and Navigation

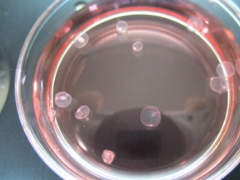

Began research on the practical application of intestinal organoids (in collaboration with the National Center for Child Health and Development)

Developed educational platforms

2018

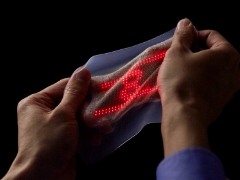

Developed an ultra-thin elastic skin display in collaboration with the University of Tokyo

Yoshinari Kitajima appointed President and Yoshitoshi Kitajima appointed Chairman of the Board

Developed mono-material film packaging

2019

Developed sheet-type coil for wireless charging of electric vehicles

Produced high-definition 8K VR content of the national treasure, the Kondo (Golden Hall) of Ninnaji Temple

Launched personal data trust bank system platform (in collaboration with Fujitsu)

2020

Developed Vapor Chamber, an ultra-thin heat dissipation component for 5G smartphones

JTB Planning Network became a consolidated subsidiary (Launched DNP Planning Network, Co. Ltd.)

Developed and started selling ultra-low reflection face shield

2021

Opened Ichigaya Letterpress Factory

Launched XR communications business to develop community co-creation spaces

Business tie-up with Irimoto Medical

2022

Development of film-type antenna for 5G-Sub6 frequency band

Started sales of DNP's high visibility pattern light, a compact lighting device

2023

Developed TGV Glass Core Substrate for semiconductor packages

Entered into a business tie-up with SCIVAX in the foundry business for nanoimprint products

Formed business alliance with CMIC Holdings and made CMIC CMO a consolidated subsidiary

Opened Image Archives Lab, offering art images

2024

Began offering reflective sheets for solar power plants