What is Recyclable Packaging for Industry Professionals

In an era where environmental sustainability has transitioned from a niche concern to a global imperative, the spotlight has intensely focused on the packaging industry. The reason is straightforward: packaging, a ubiquitous part of daily life, significantly impacts our planet's health. Enter recyclable packaging - a beacon of hope in the quest for sustainability. This innovative packaging approach addresses the mounting environmental challenges and aligns with the growing consumer demand for eco-friendly products.

See 11 related fields

See related articles

Recyclable packaging offers a pathway to reduce waste, conserve resources, and minimize the ecological footprint of packaging operations. Its relevance today is underscored by the urgent need to combat pollution, particularly plastic waste in oceans and landfills, and the pressing demand to transition towards circular economies.

By embracing recyclable packaging, industries can contribute to a more sustainable future, ensuring our products have minimal environmental impact. This article will explore recyclable packaging, its importance, benefits, and materials involved, setting the stage for a deeper dive into why it is not just a trend but a critical shift in how companies approach product packaging.

*Information accurate as of June 2024.

What is recyclable packaging?

Recyclable packaging represents a cornerstone in the sustainable packaging movement, defined by its ability to be reprocessed and reused, thereby reducing its environmental footprint. Unlike traditional packaging options, which often end up in landfills or as litter, recyclable packaging materials can be collected, processed, and manufactured into new products. Depending on the material, this cycle can be repeated multiple times, significantly diminishing the need for virgin resources and lowering the overall environmental impact.

The essence of recyclable packaging lies in its design and materials, which are selected to ensure ease of recycling post-consumer use. Materials such as paper, cardboard, glass, metal, and certain plastics are among the most commonly used in recyclable packaging solutions. Each of these materials has distinct recycling processes and rates of recyclability, influencing their suitability for various products and industries.

The differentiation between recyclable packaging and other types of packaging, such as biodegradable or compostable options, is crucial. While all these forms aim to reduce environmental impact, recyclable packaging focuses on the reusability of materials. In contrast, biodegradable and compostable materials are designed to break down under specific conditions, returning to the earth without leaving harmful residues. However, recyclable packaging could offer minimizing resource consumption and waste generation through its life cycle.

In today’s market, the distinction and promotion of recyclable packaging are vital. Consumers are increasingly knowledgeable and concerned about the environmental impact of their purchases, driving companies to adopt packaging solutions that reflect a commitment to sustainability. By understanding what recyclable packaging entails and its benefits over non-recyclable alternatives, companies can make informed decisions that align with environmental goals and consumer expectations, paving the way for a greener future.

Why should companies choose recyclable packaging?

Environmental concerns

The pivot towards recyclable packaging is not merely a trend but a response to the escalating environmental concerns gripping the globe. The extensive use of non-recyclable packaging has contributed significantly to environmental degradation, notably by accumulating waste in landfills. This waste occupies vast land areas, endangering wildlife. Recyclable packaging emerges as a crucial solution by offering a sustainable alternative that can significantly reduce waste.

By converting used packaging into new products, we limit the need for virgin materials, conserve natural resources, and minimize the ecological footprint.

Consumer demand

Consumer demand significantly sways corporate strategies in the current market landscape, especially concerning sustainability. Modern consumers are increasingly eco-conscious, favoring products and brands committed to environmental stewardship. This shift in consumer preferences is a loud and clear call for companies to adopt recyclable packaging.

By integrating sustainable practices, brands can meet this growing demand, foster a positive image, and strengthen customer loyalty. Surveys and studies consistently show that consumers are willing to pay more for products that come in sustainable packaging, underscoring the importance of recyclable materials in tapping into market trends and consumer expectations.※

Therefore, recyclable packaging is an environmental imperative and a strategic business move that can enhance brand value and competitive advantage.

-

※Reference:

"Consumers willing to pay 9.7% sustainability premium, even as cost-of-living and inflationary concerns weigh: PwC 2024 Voice of the Consumer Survey,”

PWC, May 15, 2024

https://www.pwc.com/gx/en/issues/c-suite-insights/voice-of-the-consumer-survey.html (visited, June, 2024)

"consumers are willing to pay more for green, but they would also buy additional sustainably packaged products if more of them were available and they were better labeled: Sustainability in packaging: Inside the minds of US consumers,"

Mckinsey, October 21, 2020

https://www.mckinsey.com/industries/packaging-and-paper/our-insights/sustainability-in-packaging-inside-the-minds-of-us-consumers (visited, June, 2024)

Regulatory pressure

Governments and regulatory bodies worldwide are intensifying efforts to combat environmental degradation by imposing stricter regulations on packaging waste. These regulations often mandate the use of recyclable materials and set ambitious recycling targets for companies. Failure to comply can result in hefty fines and reputational damage, making recyclable packaging a necessity rather than an option.

The regulatory landscape is also evolving, with many regions adopting Extended Producer Responsibility (EPR) schemes that hold producers accountable for the end-of-life management of their packaging.

This regulatory pressure encourages companies to rethink their packaging strategies, pushing them towards recyclable solutions to mitigate risks and ensure compliance. As such, keeping abreast of and adhering to these regulations safeguards companies from legal repercussions and positions them as responsible corporate citizens committed to environmental sustainability.

Branding

Beyond compliance and consumer demand, recyclable packaging is pivotal in branding and market differentiation. In a crowded marketplace, a strong sustainability ethos can set a brand apart, appealing to the growing segment of environmentally conscious consumers. By prioritizing recyclable materials, companies can communicate their commitment to sustainability, enhancing their brand's reputation and appeal.

This commitment can be leveraged in marketing campaigns, packaging design, and Corporate Social Responsibility (CSR) initiatives, creating a compelling narrative that resonates with consumers. Moreover, sustainable practices, including recyclable packaging, can foster employee pride and attract talent, further reinforcing the brand's positive image.

Recyclable packaging stands for more than meeting external expectations. It is also about building a brand that stands for something greater than its products-sustainability, responsibility, and innovation for a better world.

What are recyclable packaging materials for industry?

The heart of recyclable packaging lies in the materials used to create it. Selecting the right recyclable materials is paramount for industries aiming to align with sustainability goals and meet regulatory and consumer expectations. This choice impacts the feasibility and efficiency of the recycling process and influences the product's lifecycle impact on the environment.

Different materials offer varying degrees of recyclability, durability, and protection for the products they encase, thus requiring careful consideration. Industries must navigate these options, considering factors such as product type, the recycling infrastructure available, and the material's environmental footprint.

The ultimate goal is to choose materials that ensure the product's integrity and safety throughout its lifecycle and contribute to a closed-loop economy, where materials are continuously reused, reducing the need for virgin resources and minimizing waste.

|

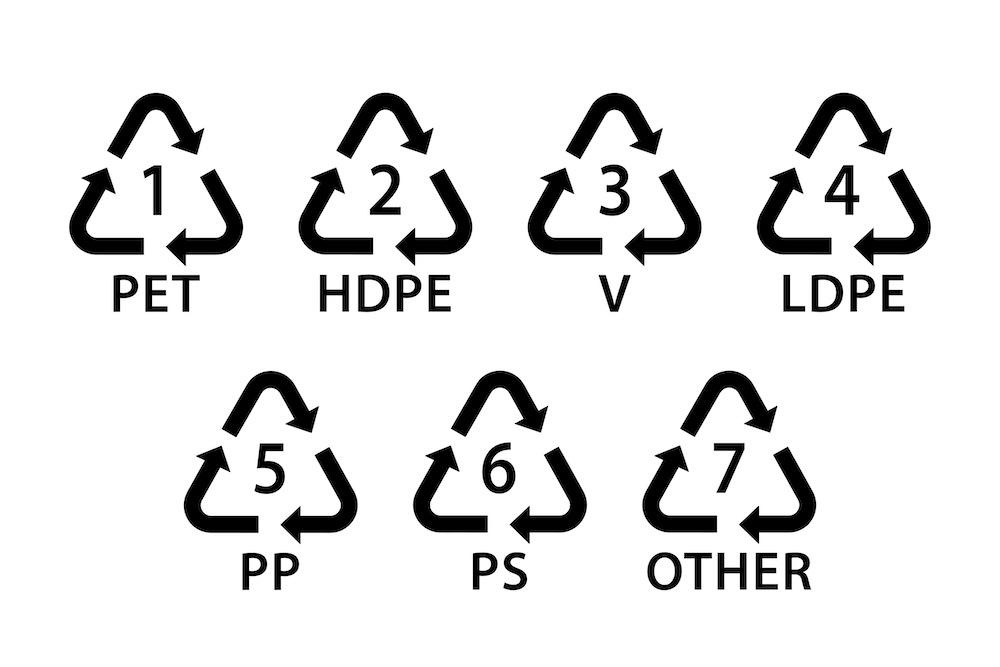

Plastic Recycling Codes

|

PET (Polyethylene Terephthalate):

Polyethylene Terephthalate, commonly known as PET, is a type of plastic renowned for its robustness, clarity, and ability to safely interact with food and beverages without altering their flavor or quality. It is lightweight, shatterproof, and highly recyclable, making it an attractive option for packaging manufacturers and environmental advocates alike.

PET's structure allows it to be easily molded into various shapes and sizes, accommodating a wide range of products. Additionally, its excellent barrier properties ensure that products contained within remain fresh and protected from external contaminants.

PE (Polyethylene):

Polyethylene (PE) is the most commonly produced plastic worldwide, valued for its flexibility, durability, and resistance to moisture. PE is available in various densities and caters to a broad spectrum of packaging requirements.

High-density polyethylene (HDPE) is tougher and used for products requiring a stronger barrier, while low-density polyethylene (LDPE) is more flexible and ideal for creating films and bags. PE's recyclability further enhances its appeal as an environmentally friendly packaging material.

PP (Polypropylene):

Polypropylene (PP) is a thermoplastic polymer noted for its resilience against chemicals, heat, and fatigue. This tough yet flexible material makes it ideal for durable and longevity packaging applications. PP is recognized for its ability to withstand high temperatures, which is essential for products needing sterilization. Its recyclability adds to its environmental value, offering a sustainable option for reducing the use of virgin plastics.

Plastic recycling methods

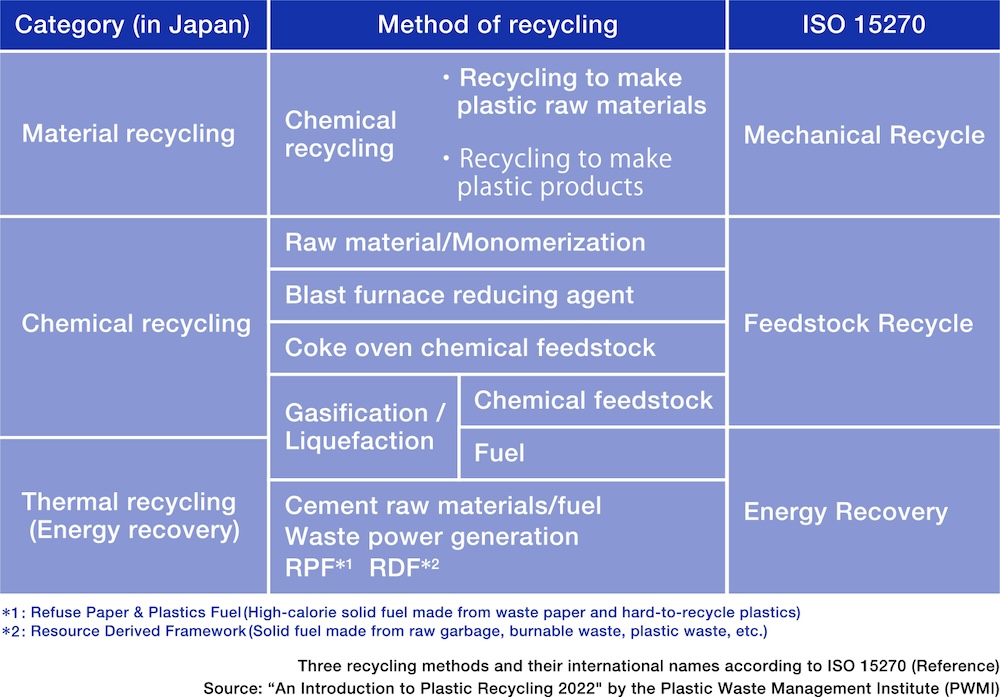

From an environmental and recycling society standpoint, it's crucial to recycle reusable materials rather than disposing of all used plastics. Plastics discarded by households and factories are recycled through the following three methods:

- 1.Material recycling

- 2.Chemical recycling

- 3.Thermal recycling

Countries worldwide are actively developing ways to utilize recyclable waste, leading to the establishment of various technologies and facilities. This article provides a detailed description of the aforementioned recycling methods. Please note that thermal recovery is not strictly considered recycling as it involves the use of thermal energy rather than actual recycling. However, it is discussed here due to its role in the effective utilization of used plastics.

|

|

Material recycling

Material recycling involves transforming used plastics into raw materials for new products. Specifically, it encompasses the process of converting plastic back into reusable materials. There are two categories within this method:

●Closed-loop recycling:

This approach recycles reusable materials back into the same product type, producing the same kind of product from waste.

●Downcycling:

When recycled materials from waste can't maintain the original product's quality, they are downgraded and recycled as raw materials for a different product. (e.g., plastic bottles transformed into materials for clothing fibers)

Advantages and disadvantages of material recycling

One of the advantages of material recycling is that waste can be used as a resource in its own country. In Japan, raw material substances (e.g., petroleum) for plastic production are primarily imported from overseas. Consequently, the country is vulnerable to supply shortages and price fluctuations due to international conditions. Effective material recycling can lead to a more stable supply of raw materials.

On the other hand, a drawback is the significant time and effort required for sorting and removing foreign materials, as single-material purity is essential for recycling.

Chemical recycling

Chemical recycling involves chemically decomposing plastic waste through various methods and converting it into other substances for use as raw materials in products. The raw materials produced through chemical recycling may differ entirely from the resources used in the original products.

There are several types of chemical recycling methods:

・Raw material/Monomerization: Plastic waste is converted back into raw material or monomer for reuse

・Blast furnace reducing agent: Plastic waste serves as a reducing agent in blast furnaces

・Coke oven chemical feedstock recycling: Plastic waste is reused in coke ovens

・Gasification: Plastic waste is gasified for industrial reuse

・Liquefaction: Plastic waste is transformed into oil for reuse

Advantages and disadvantages of chemical recycling

Chemical recycling offers the following advantages:

・

Bottle-to-bottle recycling

PET bottles are made from Polyethylene Terephthalate (PET) resin. Technologies have been established to collect used PET bottles and recycle them back into PET bottles, known as bottle-to-bottle recycling.

In bottle-to-bottle recycling, chemical recycling involves sorting, grinding, washing, depolymerization to produce PET resin feedstock (or intermediate materials), purification, and repolymerization. This advanced process breaks down plastic waste into its chemical building blocks, allowing for the creation of high-quality recycled materials suitable for various applications, including food-grade products. Chemical recycling was pioneered in Japan, offering significant advantages in processing a broader range of plastics and producing materials that meet high-quality standards.

・

Saving energy resources

Through chemical recycling, plastic waste is broken down into chemical substances like hydrogen, methanol, ammonia, and acetic acid. These can serve as raw materials for plastics, reducing agents in blast furnaces, flammable gases, and oil, among other uses.

・

Reduction of CO2 emissions

According to the Environmental Impact Report on Plastic Recycling Methods (2007) by The Japan Containers And Packaging Recycling Association, chemical recycling surpasses material recycling in terms of reducing CO2 emissions, though the extent of this advantage varies among methods. Nonetheless, chemical recycling can decrease both energy consumption and CO2 emissions compared to producing PET resin from new petroleum-based raw materials.

A drawback of chemical recycling is its tendency to require large-scale facilities, which can increase costs, as PET resin is produced from broken-down raw or intermediate materials.

Thermal recycling

Thermal recovery involves collecting plastic waste and burning it in a waste incinerator to harness thermal energy, which is then utilized to generate electricity or produce hot water. This method is also known as heat recovery or thermal recycling, serving as a disposal option for plastics that cannot be materially or chemically recycled.

Advantages and disadvantages of thermal recycling

The benefits of thermal recovery include using collected plastic waste as fuel for incinerators, thereby conserving fossil fuels typically used in waste incineration, and reducing the volume of plastic waste compared to landfill disposal.

Conversely, the drawbacks are that thermal recovery does not constitute recycling, as the plastic waste is burned, emitting CO2 during combustion. Additionally, constructing and operating a waste incineration facility for thermal recovery tends to be more costly than a standard facility. Therefore, the "Plastic Material Cycle Strategy" formulated by the Japanese government emphasizes promoting reuse and recycling while minimizing reliance on thermal recovery. Recyclable packaging benefits from material, chemical, and thermal recycling methods, each offering distinct advantages in reducing environmental impact.

Why we need Mono-materials

Material and chemical recycling are crucial for achieving the Sustainable Development Goals (SDGs) and fostering a recycling-oriented society. This is reinforced by the use of "Mono-materials." Mono-materials consist of a single material, simplifying their reuse by eliminating the need for disassembly or material separation during recycling. This approach effectively advances the 3Rs (Reduce, Reuse, Recycle) + Renewable philosophy, contributing to the creation of a sustainable society.

DNP contributes to Mono-materialization of packaging

DNP has achieved Mono-materialization of packaging for general consumer goods through our proprietary technologies, aiming to realize a recycling-oriented society.

DNP's Mono-materials technology

Traditional packaging materials are typically composed of multiple materials (such as aluminum-metallized PET, nylon, etc.), each serving a specific function to meet packaging requirements like heat and impact resistance. While these multi-materials offer excellent functionality, they pose challenges for separation (sorting), thereby complicating the recycling process.

DNP has developed the Mono-material packaging that matches the performance of multi-material packaging, leveraging its proprietary technologies honed over the years, including converting, film forming, and vapor deposition techniques. For example, we replaced packaging that traditionally used two types of materials, nylon film and PE film, with packaging made from a single material, PE film only.

DNP's Mono-material technology boasts two key features. Firstly, it simplifies recycling by eliminating the need for sorting and processing. This not only reduces the burden on the recycling process but also enhances recycled material quality.

The other feature is to safeguard the product package contents. DNP's Mono-material packaging materials utilize proprietary laminating technology to replace traditional composite materials (multi-materials). For instance, it's possible to achieve the same barrier performance (blocking oxygen and water vapor) as aluminum-evaporated PET film using only PE film.

DNP Mono-material packaging materials lineup

DNP offers Mono-material packaging materials in two types: PE (polyethylene) and PP (polypropylene).

The PE version is well-suited for liquids and heavy contents, while the PP version is ideal for packages requiring heat resistance and barrier properties. Depending on the application, these materials can be used across a broad range of products, including pouches and tube containers.

|

|

Contact DNP Global today to explore how our innovative packaging solutions can meet your sustainability goals and enhance your brand. Let's work together towards a greener future.

Frequently Asked Questions

- What are non-recyclable packaging materials?

- Non-recyclable packaging materials include multi-layered plastics, some plastic films, and, often ending up in landfills or incinerators due to their complex compositions.

- What are the benefits of introducing recyclable packaging?

- Recyclable packaging reduces environmental impact, supports a circular economy, enhances brand reputation, meets consumer sustainability expectations, and helps comply with environmental regulations.

- What are the challenges to introducing recyclable packaging?

- Challenges include higher initial costs, logistical hurdles in recycling processes, regional recycling capability variations, and the need for consumer education on recycling practices.

- How does recyclable packaging influence consumer purchasing decisions?

- Recyclable packaging attracts eco-conscious consumers, enhancing product appeal and brand loyalty through sustainable practices and clear sustainability communication.

- What future trends are expected in recyclable packaging?

- Future trends include developing easier-to-recycle materials, simplified packaging designs, using digital technologies for material tracking, and focusing on creating a circular economy.

See 11 related fields

See related articles